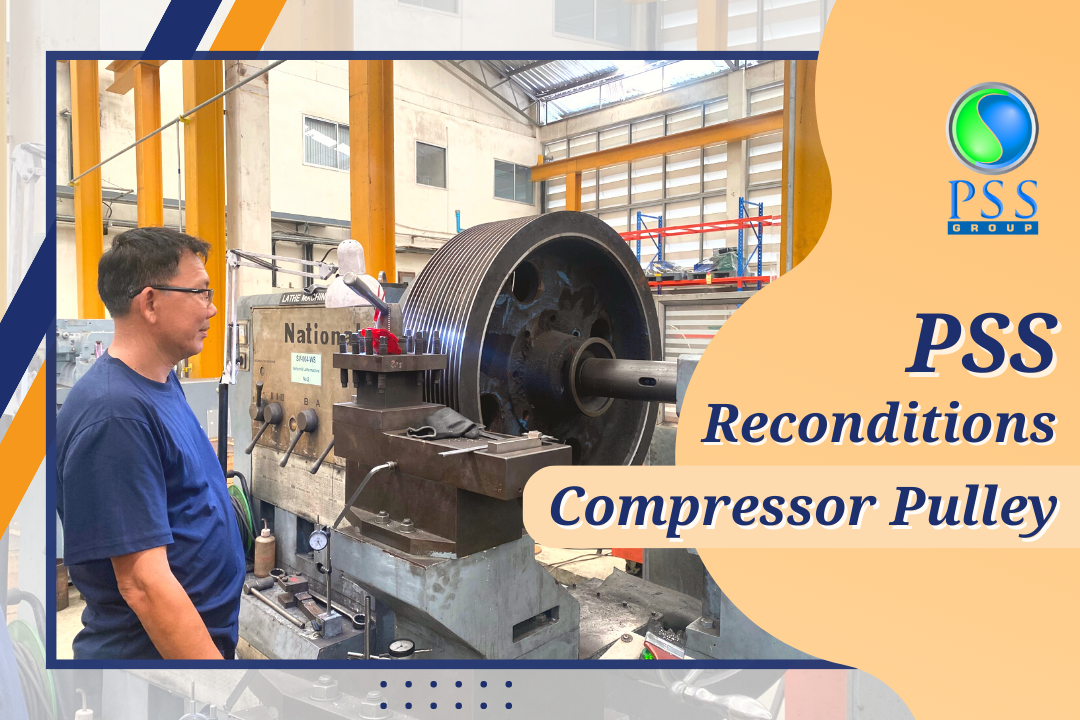

In the heart of Thailand’s major refinery, a critical compressor overhaul faced an unexpected hurdle. During the inspection by PSS Workshop, a worn-out and damaged belt groove on the compressor drive pulley was discovered. Customer did not have a spare pulley and asked PSS to find a solution.

Our engineers meticulously examined the damaged pulley, formulating a comprehensive repair strategy. The objective was clear: restore the belt groove to meet standard specs while ensuring peak performance and reliability. The challenge was in the width of the belt groove, exceeding the dial indicator’s range commonly used (10 mm length). This was not enough to ensure machining accuracy.

PSS searched for an extended dial indicator in the market and was lucky to find a rare 20 mm length version. This adaptation enabled precise measurements and adjustments, even for grooves wider than the capabilities of conventional tools. The extended length facilitated accurate work on wider belt grooves, reducing the likelihood of errors and adhering to ISO alignment standards of ±0.05 mm.

The reconditioning process was complete within 2 days and the refinery was very satisfied with PSS’s innovative solution. We have further proposed to our valued customer to to manufacture new pulleys using PSS approved foundries. Customers will now send all their pulleys to PSS for reconditioning.