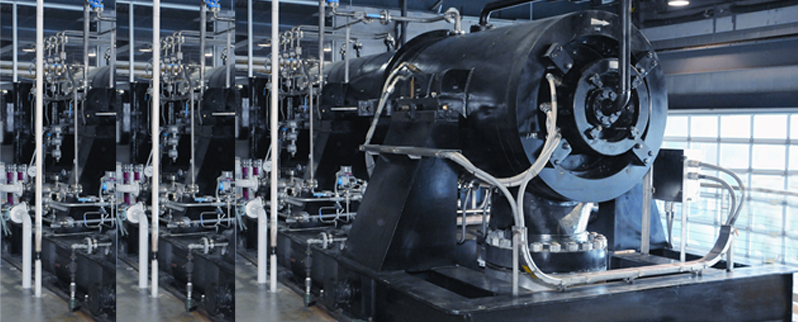

The Dresser-Rand DATUM line of centrifugal compressors was designed for maximum performance in all pressure and flow applications. Their unmatched efficiency, reliability, and ease of maintenance make them the most advanced turbo compressors available for the oil, gas and process industries.

Dresser-Rand’s DATUM ICS integrated compression system is a high-efficiency DATUM centrifugal compressor, driven by a high-speed, close-coupled motor, with an integrated centrifugal gas-liquid separation unit, packaged with process gas coolers in a single module. As a complete compression system it can be applied to all markets – upstream, midstream and downstream – with the smallest footprint, reduced weight and at the lowest total installed cost.

The Dresser-Rand DATUM C centrifugal compressor is an integrated, high-speed electric motor-driven compressor that provides a highly efficient, compact solution for all markets.

The Dresser-Rand DATUM P pipeline compressors unmatched efficiency, reliability, and ease of maintenance make these compressors the most advanced units available for natural gas transmission pipeline applications.

Standards :

The DATUM line of centrifugal compressors was designed for maximum performance in all pressure and flow applications. Their unmatched efficiency, reliability, and ease of maintenance make them the most advanced turbo compressors available for the oil, gas and process industries. Typical applications include:

- Oil and gas production—gas gathering, liquid recovery, gas lift, gas injection, pipeline boosters, gas storage, recompression, and reinjection

- Refining—wet gas, hydrogen, coker, and other hydrocarbon and utility gases

- Ethylene—charge gas, ethylene and propane/ propylene refrigeration

- Methanol—feed gas and syngas

- lNg—mixed refrigerant, propane, methane, nitrogen, and feed gas compression

- Ammonia—feed gas, syngas, refrigeration, and air compression

- Urea—CO2 compression

- Air separation—nitrogen feed, recycle and air services

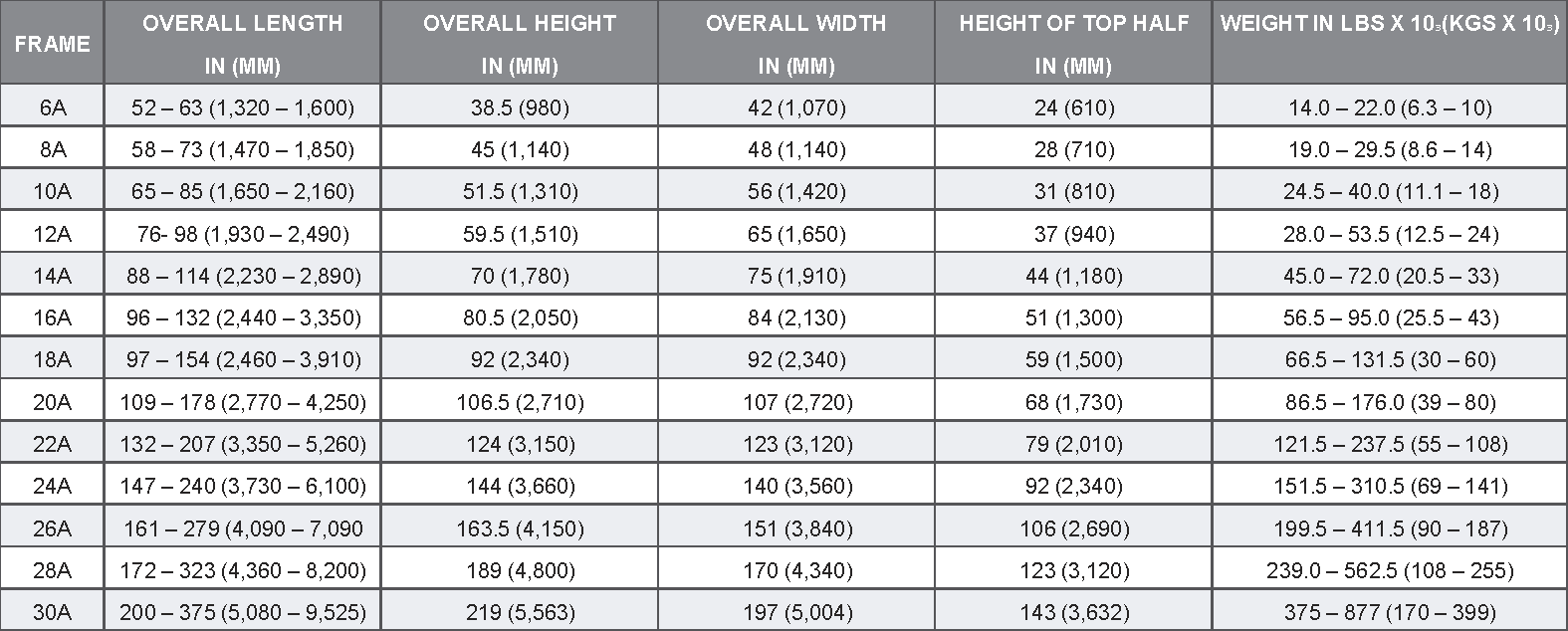

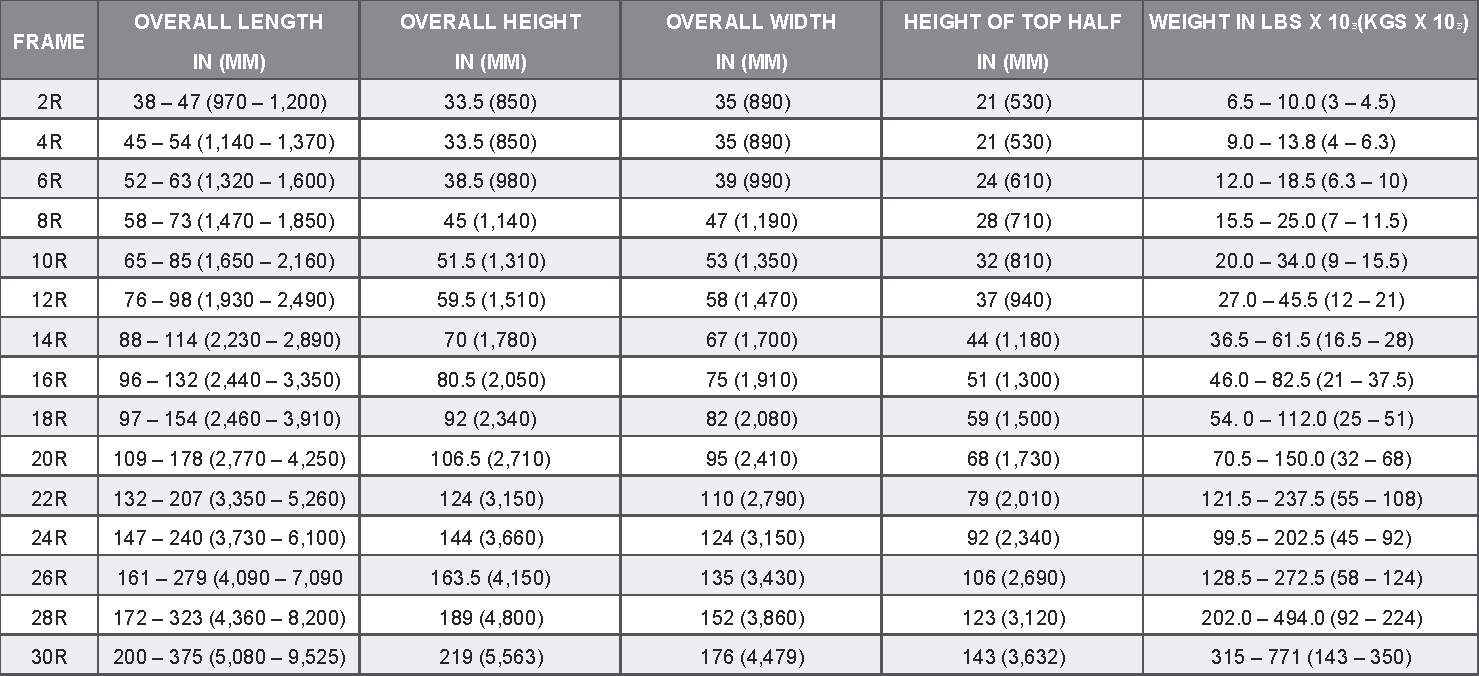

Design Ranges :

Features & Benefits :

- Emission-free design

- Quiet operation

- Reduced footprint

- No on-site leakage from shaft seals

- Magnetic bearings that eliminate the need for oil lubrication- Designed in accordance with API 610/API682(ISO 13709 / ISO 21049) specifications