This past month, PSS commissioned our first drop in pump – a split case double suction BB1 pump. This was a brilliant success with calculated power savings of about 1 MUSD per year.

The drop-in bare pump was fitted into the existing piping envelope with existing baseplate footprints and existing 1 MW motor. There were no modifications required on site – our 3D scanning of the OEM pump was perfect.

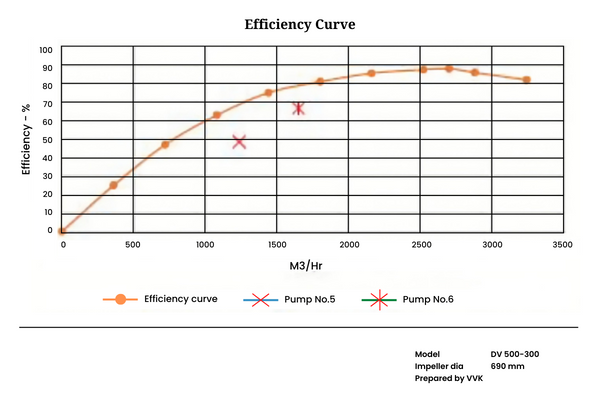

A performance test was performed on site to confirm the performance calculations that were done on our CFD program. The results were amazing:

- At BEP, PSS Pump efficiency was at 93%. Original Japanese OEM efficiency was 78% at BEP.

- Two parallel pumps supplied by OEM were running at poor efficiency levels of 66% and 48% due to old design and high wear and tear in casings and impellers.

- Translated to money, customers could save an additional 1.2 MUSD per year by converting the two pumps to PSS Pumps.

The reasons for the superiority of the PSS Pump are due to the following:

- Redesigned impeller vanes and smoothened hydraulic geometry of the casings.

- Better casting finish quality of the hydraulic parts.

- Controlled clearances at wear rings.

This pump is a major landmark in our vision to provide energy efficiency solutions to our customers. Our valued customer in this case was so pleased with the results that they have now awarded PSS an additional 2 drop in pumps.