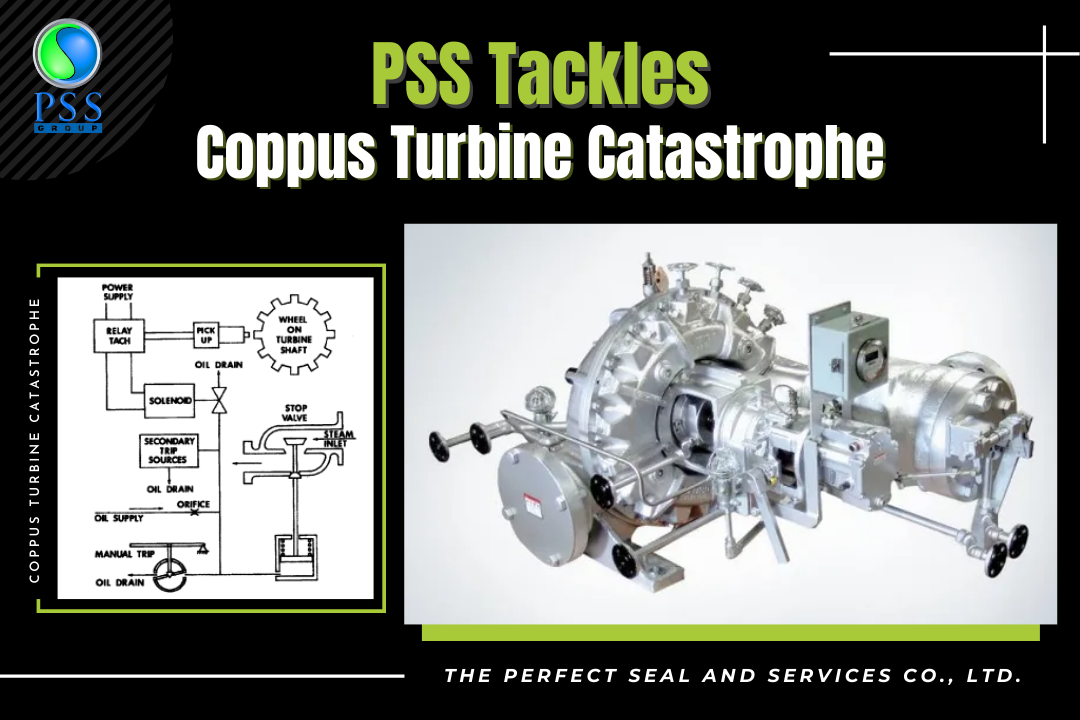

A major refinery in Thailand had a catastrophic failure on their Dresser Rand Coppus steam turbine RLHB19. The turbine was equipped with an electronic overspeed protection system which was severely damaged – including the main steam turbine shaft, trip pin assembly, multi tooth speed pickup wheel, and the tachometer. PSS did not investigate the root cause in this case but found the bearings badly damaged which could have created an abnormal runout condition. We have also asked customers to check their emergency stop valves as a small opening here will provide enough steam to drive the turbine to destruction.

Since spares were not available, our customers asked PSS to source most of the spare parts. In the past several years, PSS has been specializing in the supply of steam turbine spare parts including wheels, complete rotors, shafts, carbons seals, labyrinth/ Inpro seals, trip and valve parts, bearings, governors and castings for OEM manufacturers like Elliott, Coppus, Worthington, Turbodyne, Dresser, Terry, and many other OEM’s.

All the damaged overspeed protection parts were sourced within 2 weeks time. To reduce costs, PSS manufactured a new shaft from 4140 material in the workshop which was rough machined and then stress relieved to eliminate thermal distortion when in high temperature operations. PSS also carried out the standard run outs of fits and faces using an alignment bar. All dimensions and run outs were accurately measured to achieve concentricity and parallelism of fits and faces.

The Coppus turbine is now installed back at site and commissioned successfully.