Description :

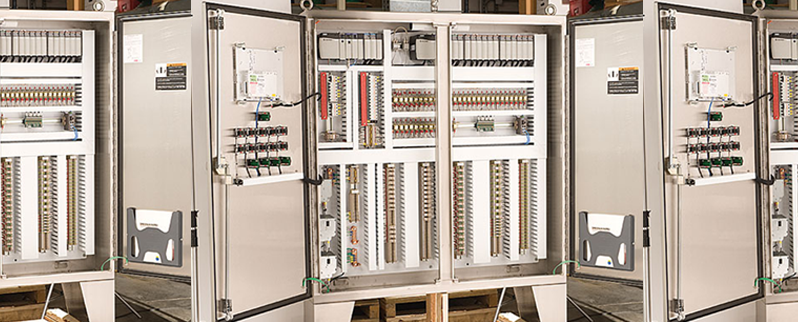

For more than 50 years, Dresser-Rand Control Systems has designed and manufactured state-of-the-art, integrated control and condition monitoring systems. We have implemented over 3,000 control systems for 17 OEMs on more than one hundred machine models. Dresser-Rand has the technology, the knowledge, and the experience to protect your mission critical rotating equipment, regardless of brand.

Standards :

Dresser-Rand Control Systems delivers safe, efficient, and reliable custom solutions within your preferred system architecture, including Control Platforms and DCS/SIS

We provide complete solutions for critical rotating equipment. Key functions by equipment type include —

- Centrifugal and axial compressors: advanced anti-sure and performance control; load sharing and performance optimization; emergency shutdown and safety systems integration

- Reciprocating compressors: control and monitoring of frame and running gear, lube oil system, cylinder lubrication, cooling water system, gas exchanger

- Gas turbines: open architecture gas, liquid, dual fuel, and DLE fuel control; anti-surge, load sharing, sequencing, and protection

- Steam turbines: extraction / admission control; integrated generator control and protection; load sharing

Through our global network of service centers, we have skilled field services and sales support teams available near you to respond quickly to any troubleshooting or application optimization need.

Design Ranges :

Dresser-Rand Envision® is a powerful and fully integrated condition monitoring suite for rotating machinery. It enables equipment operators to make educated, timely decisions regarding the control and maintenance of their mission-critical equipment, including —

- Centrifugal compressors

- Reciprocating compressors

- Gas turbines

- Steam turbines

Features & Benefits :

Users can view, analyze, and store information regarding operational events, performance trends, and failure modes.

The Envision suite combines several user interfaces into a single software program that displays process parameters and equipment control. It also conducts real-time performance calculations and vibration analysis. The software generates reports and can generate automatic email notifications to operators when alarms are triggered. Multiple compressor trains can be monitored from a single computer that can be accessed from anywhere in the world through an Internet connection. When accessing Envision tools remotely, users encounter the same experience as they would if they were physically on-site.